News

The Spindle-Type Cotton Harvester Preseason Procedures

The Spindle-Type Cotton Harvester

Preseason Procedures

Spindle pickers are complex, close-tolerance machines, requiring skilled training to operate. They also require precision shop equipment for repairs and adjustments, especially to the row units. Many producers rely on a dealer or specialty shop with trained service technicians for major repairs and adjustments. Pickers must be properly prepared to make sure they are capable of minimizing harvest losses.

Study and use the operator’s manual provided for your picker; it is the best source of information concerning adjustments. This reference gives insight into most common problems faced by picker operators, and it offers solutions to these problems. Preparation can begin with a thorough cleaning and inspection of all row units. Tighten or replace loose or missing or damaged fasteners.

Tire Condition and Pressure

Check and inflate tires to the pressure specified for that tire and picker load before making other adjustments. Low pressure in picker tires on one side can cause that side’s row unit height to be several inches lower. Low tire pressure can also promote a springing or bouncing effect of the row unit height control system. Low pressure eventually damages the tire. A damaged tire may burst and cause the picker operator to lose control during high-speed travel or cause a serious harvest delay during prime picking.

Row Unit Tilt

Row units of a cotton picker are tilted somewhat to cause the lowest spindles in the bars to enter the plants at the lowest possible height, maintaining the bottom of the row units about 1 inch above the soil. Proper tilt gives spindles a very slight vertical motion relative to the plant from entry to exit of the picking zone. Proper row unit tilt positions the front and rear spindles at slightly different heights within each plant. This arrangement leaves very little gap between spindles moving through the plants and provides greater harvesting efficiency. Tilt also provides relief at the rear of the cabinets to shed trash easier, thus reducing accumulation and dragging of shed leaves and plant debris. Faster clearing of debris reduces wear on the bottom of the cabinets.

Tilt Adjustments

Row units should attach to the toolbar with the front of the cabinet or front drum about 1-1.5 inches lower than the rear of the cabinet when positioned at picking height. Raising and operating row units higher may change the tilt slightly. Manufacturers (within the operator’s manual) typically specify a “pin-to-pin center” adjustment on the turnbuckle or adjustment link to obtain the specified tilt. Consider their specification a guide for average conditions – a starting point. Cotton fruiting very low, such as a crop planted “no-till” with little or no row bed, may retrieve much better with reduced tilt that puts the entire picking head closer to the ground. A greater amount of tilt may pick a higher percentage of larger plants with higher fruit set.

Spindles and Spindle Bushings

Picker spindles should be sharp at the front of the barb in order to grasp, hold, and pull seed cotton from the bur. Spindles tend to wear at the heights both where more cotton is picked and where more soil splashes onto the cotton before picking. Thus, wear occurs at different heights on the bars in different crop conditions. Usually, the bottom one-half to two-thirds of the spindles in a bar wear faster. Spindle wear can cause rust during picker storage, reducing aggressiveness and harvesting efficiency. Bushing wear is more rapid in the same height zones due to greater side force on spindles passing beneath the doffers.

Be sure that spindle assemblies are the correct left- or right-hand spindles to match both the nut thread and the drum where they are to be installed. The tips of the barbs should rotate into the cotton and point in the direction that the nut is turned when screwed into the bar. Immediately replace any broken or damaged spindles to prevent further damage to doffers, spindle moistening pads, and supports. Remove and identify the cause of any non-rotating or “dead” spindles – even if the bar needs removal and disassembly – to correct the problem.

Spindle Adjustments

A spindle assembly should have about 0.003- to.017-inch end play before insertion into the bar. Once it is in the bar, you should feel some slack between the drive gear in the bar and the spindle gear when rotating the spindle back and forth between your thumb and forefinger. If the spindle binds or has no slack between the gears, remove it, add shims, and retighten it until you can feel the slack. You can use a dial indicator to measure bushing wear when gauging the bar heights. Center the probe directly over the spindle between the dust collar and the start of taper on each spindle. Observe variations in the reading when forcing the spindle fully up to fully down vertically. Vertical movement in excess of 0.006 inch signals a need to replace the spindle bushings. Excess end play here may also be caused by wear of the thrust flange bushing on the base of the spindle nut.

Replacing Worn Parts

Worn thrust flanges prevent spindle gears from meshing correctly with the drive gear; this problem accelerates the wear of the drive gear. Usually, spindle bushings are replaced when new spindles are installed. Several factors can shorten spindle life, such as weather, yield, crop and soil conditions, and the amount of leaf, sand, and trash in the cotton. However, spindle and bushing life should typically be approximately 600 hours of picking (fan hours).

Bar Height and Condition

A uniform picker bar height is critical in maintaining the correct gap between the spindles and the doffers and moistening system. A low bar may not doff cotton from the spindles well; a high bar may gouge or dig into the doffers and moistening pads. Certainly, check the bar height each year before the start of the harvest season. You should also take the following steps:

- Thoroughly clean all row units, paying special attention to cleaning the base of each bar.

- Raise or remove the doffers and moisture system columns to provide clearance and easy rotation of the drums.

- Number each bar and its position in the drum with a permanent marker or steel stamp. Replace the bottom row of spindle nut assemblies in both drums with new or renewed spindle nut assemblies.

- Position the dial indicator probe on the bottom plate of the row unit to strike the top of the bottom spindle of each bar between the dust collar and the start of taper on each spindle to indicate a depression of the dial probe for each bar.

- Rotate the drum by hand, recording the bar position and the dial indicator reading (at the maximum point for the spindle) to the nearest 0.001 inch for each bar.

- After you measure all bars, scan the readings for the bar with the greatest reading (highest bar).

- Calculate the shim thickness (amount of shims) needed to bring each bar to the height of the highest bar.

- Loosen the pivot pads for each low bar, add the proper amount of shims, and retighten.

- Measure the bar heights again, and repeat the process until all bars are within 0.003- to 0.008- inch of each other.

- Reinstall/adjust the doffer and moisture system columns to within 0.003-inch of the closest spindles.

Note: Doffers should barely touch the spindles in the highest bar. If a feeler gauge is not available, a crisp dollar bill should slide with slight drag between the doffer lugs centered over the high point on the spindles.

Doffers

Doffers remove the seed cotton from the spindles with an unwinding, wiping, and stripping motion toward the end of the spindle. The surface speed of the doffer is many times faster than the surface rotation of the spindle. Follow these tips to maintain the doffers:

- Doffer lugs should operate within about 0.003 inch from the spindle surface.

- When crop conditions are very good, doffer-to-spindle clearances of as much as 0.020 inch may doff very well.

- Do not lower a doffer column first before determining the cause of poor doffing. At times, this action only accelerates the wear of the doffers, spindles, and bushings without improving doffing appreciably.

- The doffer material must be flexible enough to allow seed cotton, trash, and other material to pass between the lug and the spindle without damage. Weather, sunlight, and other factors may age and harden doffers.

- Severely worn doffer lugs have reduced clearance for seed cotton to pass between the plate and the spindle. This problem can increase cracked seed, which is particularly important when cotton is harvested for planting seed.

- Polyurethane (beige colored) doffers have reduced wear or “shavings” that are less prone to contaminate lint.

- Doffer lugs with leading edges that become rounded from wear are less effective and should be reground or replaced with doffers with sharp leading edges. One cause of wear and rounding of the doffer lug leading edge is poorly shimmed bar height. It may also cause frequent spindle wrap and twist on low bars.

- Replace doffer columns that have broken, torn, or rounded-edge doffer lugs with a properly ground doffer column. Adjust the height correctly.

- See your operator’s manual for a recommended doffer adjustment procedure.

- Here is one effective doffer height adjustment method: Power the row unit slowly using your tether. Lower the doffer column slowly while listening for a regular “thump, thump, thump” as the bars pass beneath the doffer column (use a stethoscope or a screwdriver from the doffer column bearing area to your ear). Then, slowly raise the adjustment until the thumping sound becomes faint to undetectable. This method also confirms that bar height is nearly correct when the thumps occur at regularly spaced intervals. Bar height needs to be serviced when the thumps you hear are random or at irregular intervals.

Some row units are adjusted at the bottom of the doffer column to assure that the column is correctly positioned in relation to the bar. Follow your operator’s manual for alignment instructions. Inspect daily and ensure that all mounting hardware for doffer and moisture pad columns are tight. Routinely remove trash, dirt, and grease accumulation from the doffer column enclosure. Removing this buildup may prevent conveying chokes.

Spindle Moistening System

The purpose of the spindle moistening system is to constantly supply cleaning solution onto the spindles to remove plant gums and resins. This cleansing helps keep the spindles aggressive and easier to doff. The solution removes plant residue while seed cotton wipes the spindle, much like a dish cloth washing flatware. A cleaning solution mixed to the correct concentration is essential for proper function. Follow these recommendations to properly maintain and use the moistening system:

- Clean any “gummy” or hardened residue from the bottom of the tank and flush the tank before the start of the picking season.

- Clean the strainers and sediment bowl daily before picking.

- Fill the tank to approximately 80% of capacity with clean water and add the proper amount of spindle cleaning solution to the tank (approximately 2 ounces per gallon of water or 1.6 gallons per 100 gallons of water). Finish filling the tank with water.

- Bulk premixing of the spindle-cleaning solution decreases the time needed for filling the tank if you have a solution trailer.

- Both picker manufacturers offer their own spindle-cleaning agents. Refer to your operator’s manual and the dealer for the best spindle cleaner for your crop conditions. A mild dishwashing detergent may do the same job once the correct solution ratio for your crop conditions is identified.

- Operate the fan system powering the spindle moistening system pump. Check the pump pressure, remove the spray nozzle at the top of the moisture pad column, and see if the spray pattern is full and uniform. Remove the nozzle from its body, clean or replace the nozzle, and then check each moisture pad in both columns of each row unit to verify that sufficient solution is going to each spindle.

- Adjust the moisture pad column so that the fins on the pads just touch the spindles as they pass beneath the pad.

- During the day, routinely remove trash (especially cockleburs) and dirty seed cotton from the moisture pad zone. However, limited lint residue on the pads may help distribute cleaning solution to the spindles.

Picker Ribs

Picker row units clean, in addition to removing the seed cotton from the plant. The rotating spindle slings locks of seed cotton against the ribs as they leave the row, knocking burs and sticks off before cotton enters the doffer and air conveyor. Spindles work with the ribs to perform centrifugal cleaning much like a cotton gin. These tips will help you maintain the picker ribs:

- Poorly spaced, damaged, or loose ribs may contact bars and/or spindles. This problem causes unusual wear and could potentially spark a fire in the row unit. The spindles, spindle nuts, and bars should not contact the ribs as they rotate.

- Missing ribs will fail to clean burs, sticks, and leaf trash from the seed cotton as it is picked from the stalk.

- Inspect the mountings and fasteners at the ends of the ribs for wear, and replace missing fasteners or damage as needed.

- All ribs should be similar to a new rib. They should not be misshapen or have free movement within the mountings.

Compressor Door Considerations

Plant lifters should be adjusted to gently lift lower bolls into the lowest and second lowest spindles of the front drum. This may require heating and bending in extreme situations.

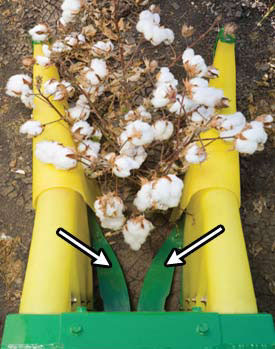

Compressor doors should press the plant and open cotton bolls against the spindles. They should have the capability of moving away from and protecting the picking mechanism from damage by large plant volumes, large-diameter stalks, or chunks and rocks passing through each row unit. Doors are hinged and supported by adjustable springs. Rotating or tightening the shaft retaining the springs increases the pressure applied by the compressor door. Ribbed “scrapping” inserts are often fastened to the row side of the compressor door to promote a more aggressive contact with bolls toward the entry and plant exit. These steps will help you maintain compressor doors:

- If the compressor door hinges are worn excessively, the door fails to move smoothly as the volume of stalks varies along a row. The door may drag on the frame of the row unit. Tension springs may break and thus apply less tension to the compressor doors. Inspect and repair or replace worn or damaged hinge pins, mounting holes, scrapping inserts, and tension springs as needed.

- Reinstall compressor doors upon completion of row unit maintenance and check for smooth movement without drag. Shim if necessary.

- Adjust the tension springs to approximately 10-15 foot-pounds on the front doors and 30 footpounds on the rear doors (starting point) using a torque wrench.

- Gap the spindle tip from the pressure door from 1/8- to 1/4-inch clearance on all doors.

- If dropped cotton lies to the left side of the base of the stalks, check spindle-tip-to-pressuredoor clearance and adjust the gap if needed. Increase spring pressure in approximately 5 foot-pound increments (one hole). Begin with the rear doors and then alternate to the front doors, “tweaking” spring tension. Evaluate each adjustment by any improvement or reduction of unpicked seed cotton. Adjust, pick, and check behind the picker before making additional changes.

- Install scrapping inserts, tighten compressor door springs, and adjust spindle-tip-to-pressuredoor clearance to clean the stalks of seed cotton if picking once over when few green bolls remain on the stalk.

- Always check that spindle tips do not contact the compressor door assemblies before operating the picker.

- Cotton crop conditions are considerably different in more arid regions where crops are irrigated than in the rain-belt regions. Cotton plants grown in dry conditions tend to be short, wide, and “bushy” with the bulk of the yield concentrated in the lower 20 inches. Sometimes, passage of the large concentrated crop volume through row units causes field loss. General recommendations are to initially set pressure doors quite loose, and then tighten them as needed to improve picking efficiency. Do not use scrapping plates for front or rear drums if limbs are brittle as a result of a freeze.

Plant Lifters

Plant lifters must float with the contour of the soil surface, gently guiding the open bolls into the row unit. They need to operate within 1 inch of the surface without plowing soil or dragging leaves. These guidelines will help you maintain the lifters:

- The plant lifters’ height should be only low enough to guide the lowest bolls into the bottom spindles.

- Adjust spring tension so only a few pounds of force are required to raise the plant lifters.

- Plant lifters should not continue to bounce after the row unit height sensors raise or lower the row units at full picking speed.

- Operating plant lifters too close to the ground when the lowest bolls are several inches higher on the stalk causes undue wear. This mistake also provides potential for unwarranted damage that might occur if lifters drag on or plow into soil or obstructions.

- Set the front tip of a plant lifter approximately 1 inch above the front lower edge of the cabinet. This placement will help the bottom of the lifter to slide rather than plow when it contacts the soil.

- Raise the height adjustment to minimize dragging leaves and plant debris.

- Use the stalk lifter guides to raise the lower bolls up to the level of the second from the bottom spindle when bolls are set close to the ground. These settings may need to be adjusted for different row bed shapes.

- If you know that large rocks, bricks, chunks, and debris are present, consider removing the stalk guides to minimize the risk of damage to row units. However, this action will likely increase seed cotton losses.

Row Unit Operating Height and Height Sensing

The best operating height for row units may be a compromise due to plant size, soil type, soil surface, shed leaves, plant debris, other obstacles, ground speed, and field terrain. Ideally, the bottom spindle on the front drum enters the row just below the bottom bolls. Where bolls have set 5-8 inches above the soil and cotton has grown on a relatively smooth row, this goal is easy to reach. Operating the row units at fairly high setting provides several benefits:

- Less contact with obstacles

- Less dragging of leaves and debris

- Reduced wear and damage of the row units

- Greater ground speed – higher productivity

Lower Boll Set Factors

Lower boll set, rows with no or slight beds, or fields rutted by erosion or containing obstacles usually cause some yield sacrifices due to higher stalk and ground seed cotton losses. A lower picking unit reduces speed and the capacity of the picker, and it increases potential for damage and wear of the row units. For low-visibility night operations, choose fields or areas within fields where the cotton fruits higher and the likelihood of obstructions is lower. Simply raising row units as little as 1/2 inch can reduce dragging of shed leaves.

“Hunting” Procedures

Constant raising and lowering of the row units (“hunting”) by the automatic height-sensing system will cause more seed cotton losses along the row and greater wear of the row unit mechanisms. Height-sensing shoes should be set for the average of the row units controlled by that sensor shoe at the chosen field speed of the picker. If a picker height sensor cycles – “begins to hunt” – as the picker moves along the rows, take these steps:

- Check the tires for proper inflation pressure.

- Check the ground speed.

- Check the oil flow and electronic settings to the sensors.

- Try reducing or increasing picking speed by as little as 1/10 mph. Sometimes, a small speed change may reduce or eliminate the cycling.

Inspect the tracks left by the sensing shoe to find out if a system is adjusted properly. A smooth, even track along the row indicates fairly constant height positioning. A heavy track followed by little or no track several yards down the row may suggest excessive cycling.

Air Conveyance System

Reliable seed cotton conveyance from each picking unit is essential. Consistent seed cotton movement depends upon adequate air volume delivery by the fan to the cotton conveyor duct. All air ducts must be free of holes, duct connections must be tight, and the air system must be free of sharp edges where lint collects (roping) or debris accumulates. Follow these rules to maintain air conveyance systems:

- Inspect and correct all air piping to ensure that there are no holes, kinks, or sharp turns in the air ducts and that all ducts are connected and secured with clamps and have no air leaks.

- Set the engine throttle and fan speed to the manufacturer’s recommendations.

- Duct air velocity should be approximately 5,000 feet per minute, measured in the straight duct’s midsection between the row unit and the cotton discharge. A flow rate equal to 20 cubic feet per minute per pound of seed cotton conveyed is recommended for air conveyor systems. Have a service technician measure this rate if conveyance problems persist. Manufacturer specific airflow requirements may be suggested in dealer service publications.

- Inspect and clean the door/transition, discharge, and air separation areas several times each day, depending upon these operating conditions:

- Picking in green or less mature cotton

- Air humidity is high during morning and late-evening operation

- After greasing the row units

Row Tracking and Correction

Guidance system sensor shoes

Row unit spacing must match the planter spacing for the row pattern being picked. Attempting to pick row patterns that are not simple subsets of the planter will result in an odd row or rows that have varying spaces as you progress down the row. For example, if you try to pick cotton planted with a 10-row planter using a 6-row picker, there will always be one pass of the picker on well-spaced rows, followed by one or more passes on poorly spaced rows. This problem will result in much higher picker losses at places where the drills from two planter passes diverge.

Row Guidance Systems

Automatic row guidance provides more uniform row spacing between planter passes than a skilled, unaided operator can obtain at planting. Guidance systems with sensors to detect and correct the position of the row unit relative to the stalks in a row reduce operator fatigue and hold the picker on the row at faster picking speeds. They are capable of reducing field losses when the row units would otherwise vary off the row under manual control.

Guidance System Adjustments

Poor plant stands in rows where the stand was damaged by standing water, weed infestations, inadequate moisture at planting, or other problems renders the guidance system less effective and may require temporary manual control. Set the guidance system sensors so the stalks enter the row unit halfway between the ribs and compressor door of the front drums.

Newer guidance systems have electronic adjustment from the cab. Setting the sensors on older guidance systems and checking the new systems require starting the picker down the row with the guidance system in operation and then stopping the picker with the hydrostat lever. After stopping, determine the positions of the ribs and spindles relative to the stalks being picked and adjust the unit to drive left or right as needed. You may need to repeat this procedure several times while making adjustments. However, once the system is set, it should not require additional adjustments unless the sensors become bent or damaged.

Categories

News

Contact Us

Contact: Agriculture Machinery Parts

Phone: 86(0)15869109368

Tel: 86-571-89967020

E-mail: dawopu@gmail.com

Add: Hangzhou City Zhejiang Province China